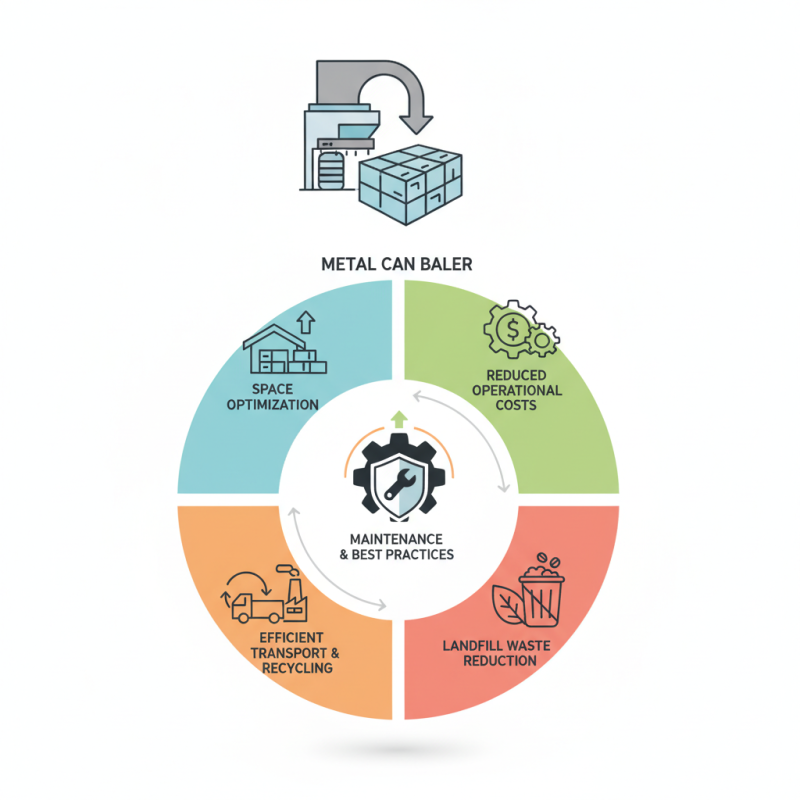

In the recycling industry, the "Metal Can Baler" plays a crucial role. John Smith, a leading expert in waste management, remarks, “Efficient baling can transform how we handle metal waste.” This machinery not only optimizes space but also enhances the processing of metal cans.

Metal can balers compress used cans into dense bales. These bales are easier to transport and recycle. They reduce landfill waste significantly. Every day, businesses rely on metal can balers to streamline their operations. Yet, some companies overlook maintenance, leading to inefficiencies.

The benefits of a metal can baler extend beyond mere space-saving. Reducing operational costs is a major advantage. However, improper usage can cause issues, prompting reflection on best practices. A well-maintained baler ensures safety and productivity. Many in the industry still struggle with these innovations. Understanding these features is vital for success.

Metal can balers play a vital role in recycling and waste management. They compress aluminum and steel cans into manageable bales. This process reduces storage space and enhances recycling efficiency. According to industry reports, recycling metal saves 95% of the energy needed to produce new cans. This impressive statistic emphasizes the importance of using metal can balers.

When considering the features of a metal can baler, look for automatic systems. These machines improve processing speed and reduce labor costs. A well-designed baler also minimizes residue. This factor is crucial, as dirty cans can lower recycling quality. Users often overlook the importance of regular maintenance. Ensuring all components work effectively can prevent costly downtime.

Tips: Always check for safety features when purchasing or operating a baler. Regular inspections can help identify potential issues. Training staff on proper loading techniques can maximize baler efficiency. Remember, a well-maintained baler can lead to a significant reduction in operational costs over time.

Metal can balers play a crucial role in recycling. They compress metal cans into compact bales. This process saves space and makes transport easier. The efficiency of these machines reduces overall waste. Recycling becomes more manageable when metal can balers are in place.

The key benefits are numerous. They minimize labor costs, allowing operators to focus on other tasks. Additionally, baled metal is more valuable in the recycling market. However, some users might struggle with setup and maintenance. Regular checks are essential to ensure optimal performance. It's also important to train staff properly. Mistakes can lead to delays and increased costs.

Metal can balers enhance recycling efforts significantly. They transform loose cans into manageable bales, boosting productivity. Yet, there’s always room for improvement in one’s approach. Staying updated on best practices can make a difference.

| Feature | Description | Benefit |

|---|---|---|

| High Compression Ratio | Efficiently reduces the volume of metal cans. | Saves space in recycling facilities, allowing for better logistics. |

| Automation Features | Automatic feeding and baling processes. | Reduces labor costs and increases processing speed. |

| Durable Construction | Made with heavy-duty materials for long-lasting use. | Lower maintenance costs and longer equipment lifespan. |

| Safety Features | Integrated safety systems to protect operators. | Creates a safer working environment, reducing injury risks. |

| Compact Design | Space-saving models that fit in limited areas. | Maximizes facility space utilization for better operations. |

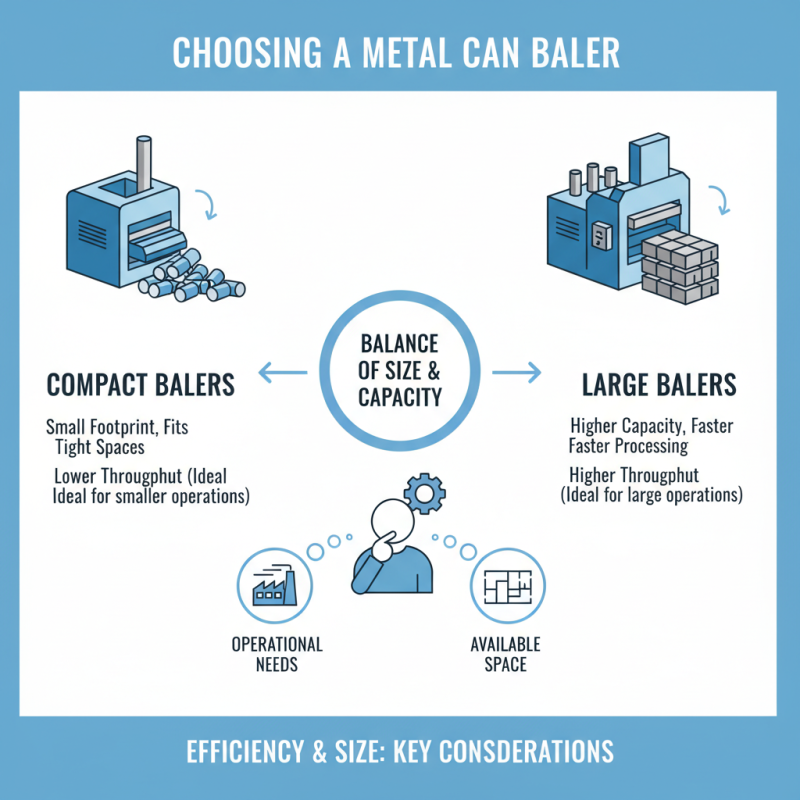

When choosing a metal can baler, consider its efficiency and size. A compact baler can fit into tight spaces. But larger models offer higher throughput. Think about your operational needs and available space. A balance between size and capacity is crucial.

Look for safety features. Guards and emergency shut-offs ensure operator safety. Regular maintenance accessibility is important too. This prevents downtime and extends the baler's life. User-friendly controls can simplify training for new staff.

Don’t overlook energy consumption. Some balers are more efficient than others. An energy-efficient model can save costs in the long run. Also, consider how it handles different can sizes. Versatility is key for varied operations. Strive to find the right mix of features for your unique needs.

When considering metal can balers, it's important to explore the various types available. Each offers unique features and benefits. For instance, vertical balers are compact. They fit easily in smaller spaces. They can handle lower volumes of metal cans efficiently. On the other hand, horizontal balers are more robust. They are suitable for larger operations. They can process higher volumes, which is ideal for recycling centers and large manufacturers. According to industry reports, horizontal balers can improve efficiency by up to 30%.

Another option is fully automated balers. These machines minimize manual labor. Benefits include enhanced safety and reduced operational costs. However, they also require significant investment. A study highlighted that automated balers can lead to a 50% reduction in labor costs. It's crucial to weigh these factors. Investing in a baler should align with specific operational needs.

Tips: Always assess your volume needs. Determine whether a vertical or horizontal baler suits your operation. Consider maintenance and parts availability. Understanding these aspects can lead to better long-term decisions. Don't overlook the potential energy savings with modern balers. They can reduce your carbon footprint while enhancing productivity.

Proper maintenance of metal can balers is essential for optimal performance. Regular inspections help identify wear and tear. Check belts, blades, and hydraulic fluids routinely. This can prevent costly downtime. Signs of excessive wear should not be ignored. Small issues can escalate if left unattended.

Cleaning is equally important. Dust and debris can cause malfunctions. Schedule regular cleaning sessions to maintain efficiency. Use air or a vacuum to clear out any buildup. Lubricate moving parts to ensure smooth operation. Over time, neglecting lubrication can lead to a breakdown.

Operators must be trained well. Misuse or lack of knowledge can lead to accidents. Encourage operators to report any strange sounds or movements. This proactive approach can prevent potential issues. While maintenance is vital, it’s also an area that often gets overlooked. Reflecting on past maintenance routines can lead to improvements in performance.