Choosing the right Scrap Metal Press Machine is essential for any recycling business. Industry expert James Anderson once shared, “A good press can transform waste into valuable resources.” This statement highlights the importance of careful selection in maximizing efficiency and profitability.

When selecting a Scrap Metal Press Machine, consider factors such as size, capacity, and functionality. A machine that is too small may not handle your workload efficiently. On the other hand, an overly large machine can lead to unnecessary costs. Focus on what fits your operation best.

Moreover, each machine has its quirks. Some may require additional maintenance or space. Reflecting on machinery can reveal potential pitfalls. What seemed perfect initially might not perform as expected. Thus, do thorough research. Understand your needs to make an informed decision.

Scrap metal press machines play a crucial role in the recycling industry. They help to compress and reshape scrap metal for easier handling and transport. This process can significantly reduce costs and maximize profits for recycling businesses. Understanding these machines is essential for enhancing efficiency and sustainability.

Choosing the right scrap metal press machine involves various factors. Look at the machine’s capacity, size, and design. How much scrap metal will you process daily? What types of materials will you use? Many machines are versatile, but some may not handle specific metals well. It's important to evaluate the operational requirements based on your unique needs.

Often, businesses overlook maintenance. A neglected machine can lead to increased downtime. Regular checks and servicing are important. You might find some machines easier to maintain than others. Understanding the nuances of each option can help prevent costly mistakes. Reflecting on these details will guide you toward making an informed decision.

When selecting a scrap metal press machine, key features play a crucial role. One important aspect is the machine's capacity. A machine with a higher tonnage can effectively process larger volumes of metal. According to industry reports, machines with a capacity of 50 tons or more are ideal for heavy-duty applications. However, these may require more power and space, which could be a drawback for smaller operations.

Energy efficiency is another vital feature. Efficient machines reduce operational costs significantly. Reports indicate that energy-efficient models can lower electricity consumption by up to 30%. This can lead to substantial savings over time. Nevertheless, these high-efficiency machines often come with a higher initial price.

Durability should not be overlooked. Machines made of high-quality materials last longer in harsh environments. However, some cheaper models, while attractive, may need frequent repairs or replacements. This can lead to downtime, affecting overall productivity. Choosing a durable machine may require a greater upfront investment but can be cost-effective in the long run.

When choosing the best scrap metal press machine, evaluating the performance and efficiency of different models is crucial. A report from the American Metal Market indicates that the efficiency of scrap metal recycling has improved by approximately 20% over the past decade. This increase is largely due to advancements in machine technology. Machines with higher compression ratios can process more material in less time. They also reduce energy consumption, a key factor in operational costs.

Tips: Look for machines that offer adjustable settings. This feature allows for flexibility based on material type. A model with a high cycle rate can also enhance productivity. It's essential to consider maintenance requirements. Some machines may demand frequent repairs, which can lead to downtime.

Another aspect to ponder is the machine's durability. The lifespan can vary widely across models. Some might perform well initially but fail to deliver long-term results. According to industry data, machines that are robust tend to yield better ROI. However, there are always trade-offs. Expensive machines may not always outperform more affordable options if the latter are better suited for your specific needs. Be critical of your choices.

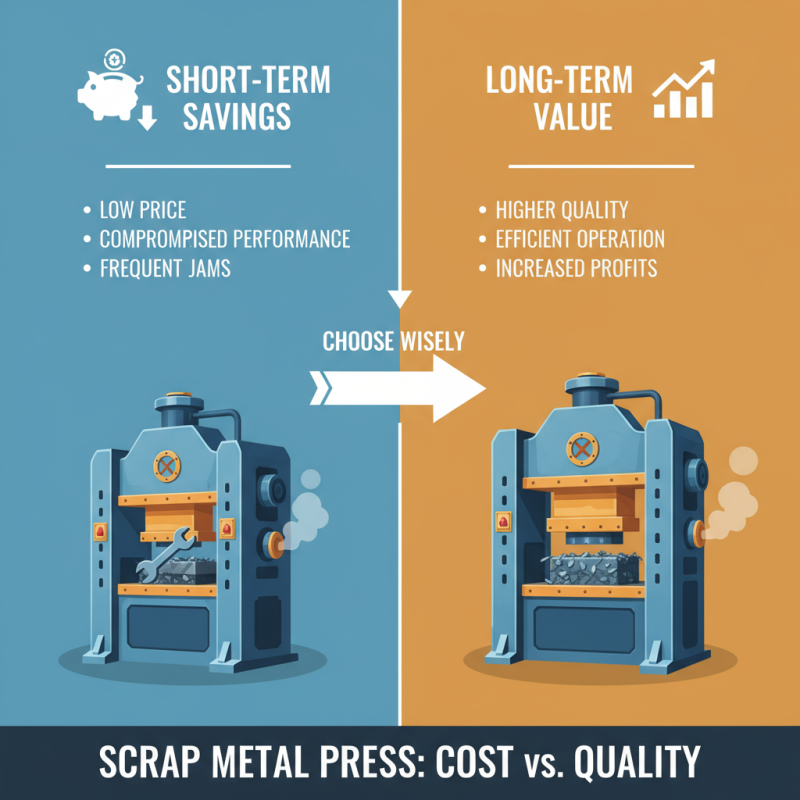

When choosing a scrap metal press machine, cost and quality are critical factors. A low price may seem attractive, but it often leads to compromises in performance. These machines should handle heavy materials efficiently. If they jam frequently, it increases operational downtime and reduces profits. So, think about long-term value over short-term savings.

Consider the materials you'll process. If you need to handle high volumes, investing in a durable machine is wise. Some cheaper models might break down more quickly. It’s tempting to choose the lowest option available, but the hidden costs can add up. Repairs and maintenance can drain your budget. Always weigh these factors carefully. Look for machines that offer good warranties and support.

Finally, don't forget user reviews. They provide insight into real-world performance. Seek feedback from others in your industry. A good machine is often the result of careful consideration and research. Keep track of your needs and budget. Sometimes, the best choice is not the cheapest one but the one that offers the best combination of quality and efficiency.

Maintaining your scrap metal press machine is crucial for longevity. Regular inspections can help identify wear and tear early. Check hydraulic systems and electrical components routinely. Issues often arise where oil leaks or electrical connections weaken. Address these problems immediately to avoid costly repairs.

Cleaning is another essential aspect of maintenance. Dust, debris, and metal shavings accumulate over time. Ignoring this can lead to overheating or reduced efficiency. Use compressed air and brushes to keep the machine clean. Pay special attention to moving parts. Lubricate them according to the manufacturer’s guidelines.

Training staff is indispensable. Even with a good machine, improper use can lead to issues. Regular workshops on machine operations can prevent mistakes. Encourage operators to share their experiences. This can highlight potential pitfalls and create a culture of safety. Reflecting on past errors can lead to better practices.