In today's world, effective metal recycling is crucial. Ferrous balers play an essential role in this process. They efficiently compress scrap metal into manageable bales. These machines streamline recycling operations and enhance productivity.

Selecting the right Ferrous baler can significantly impact a business. It improves efficiency and reduces operational costs. Quality balers can handle various types of ferrous materials, making them versatile. However, not all balers are equal in performance and features. Some might lack in durability or require frequent maintenance.

Understanding the options available is essential for making informed decisions. Some balers might seem perfect at first glance. Yet, they could leave room for improvement. Analyzing key factors like size, capacity, and ease of use is vital. Ultimately, choosing the best Ferrous baler can lead to better recycling practices and a greener environment.

Ferrous balers play a crucial role in the metal recycling industry. They efficiently condense scrap metal, mainly iron and steel, into manageable bales. These bales simplify transportation and storage, making the recycling process more efficient. According to a recent study by the Institute of Scrap Recycling Industries (ISRI), around 25% of all steel produced globally comes from recycled materials. This highlights the importance of effective baling systems in boosting recycling rates.

The operational efficiency of ferrous balers is impressive. For example, modern balers can process up to 30 tons of scrap metal per hour. This speed is essential in keeping up with the high demand for recycled steel. However, challenges remain. Many facilities still struggle with outdated equipment, leading to increased operational costs. Reports indicate that about 40% of recycling centers have not upgraded their baling technology in over a decade. This stagnation can hinder growth in recycling efforts.

Additionally, safety is often overlooked. Inadequate training for operators can lead to accidents. According to OSHA, improper handling of balers is a common cause of injuries in recycling plants. Facilities must prioritize safety training alongside equipment upgrades to protect their workforce. Balers are vital, but a comprehensive approach to safety and efficiency is equally necessary in the recycling sector.

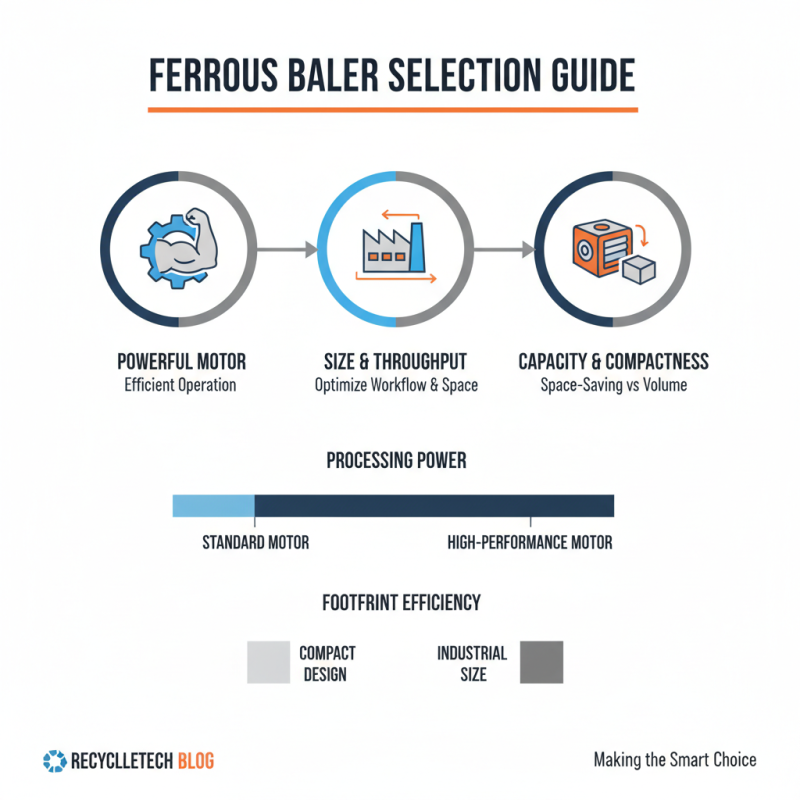

When selecting a ferrous baler, several key features must be evaluated. Look for one with a powerful motor. Adequate power ensures efficient operation. In addition, consider the baler’s size and throughput. It needs to fit your space while managing your workload. A compact design can save space but may limit capacity.

Durability is another crucial aspect. Balers operate under tough conditions. Heavy-duty materials can withstand stress and last longer. Keep an eye on maintenance requirements too. Some balers demand frequent upkeep, which can be a hassle. A machine that requires less maintenance can significantly reduce downtime.

Lastly, examine the baler's safety features. Operating with heavy machinery can be risky. Safety guards and automatic shut-off systems are essential for protecting workers. If a baler does not meet safety standards, it might compromise efficiency. Reflecting on these factors leads to a more informed decision.

Optimizing metal recycling efficiency requires choosing the right ferrous balers. These machines compress metal scrap into bales. This process saves space and enhances transport efficiency. A good baler can significantly increase workflow in recycling facilities. Selecting the right model can improve productivity.

Many balers offer features like automated tying systems. These features reduce labor costs and time spent on operations. However, different facilities have varying needs. Some may require more compact machines while others need heavy-duty options. It's important to evaluate your specific requirements. Sometimes, an oversized baler may not be the best fit.

Maintenance is crucial for longevity. Regular checks can prevent breakdowns that hamper productivity. Small issues can turn into costly repairs if neglected. Balers also need space for efficient operation. Forgetting to account for space can lead to operational headaches. Investing time in proper training for staff can help avoid mishaps. A well-trained team contributes to overall efficiency and safety.

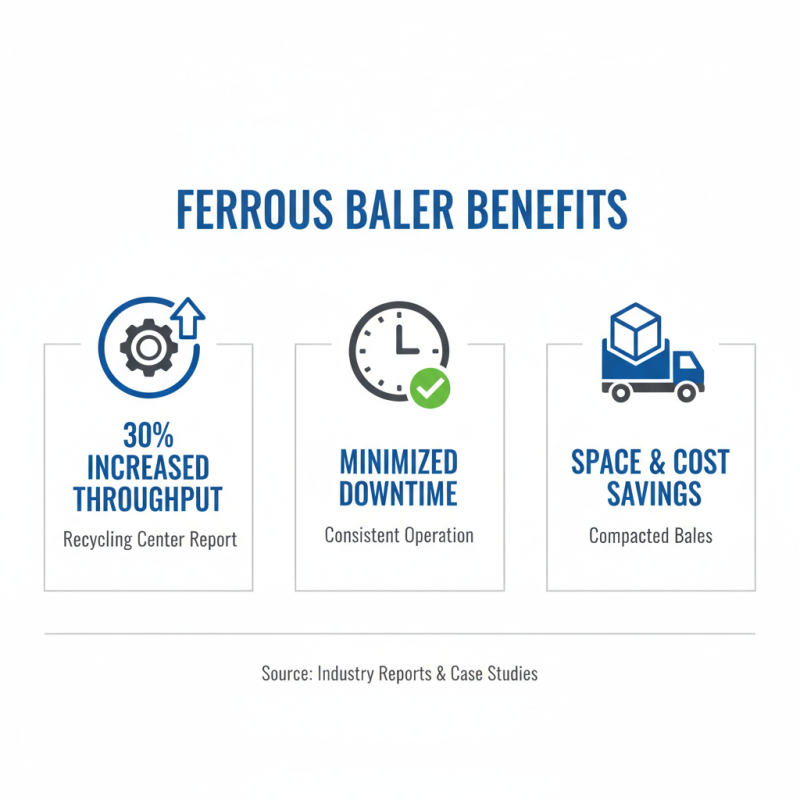

When assessing ferrous balers, performance and cost are key factors. In 2022, the global metal recycling industry was valued at approximately $285 billion. Ferrous balers serve as essential tools in this market, handling scrap steel and iron efficiently. A comparative analysis reveals that balers streamline operations, reducing labor costs and increasing throughput.

Performance varies significantly among balers. High-capacity models can process up to 30 tons of metal per hour. While these machines may have higher upfront costs, they offer long-term savings through efficiency gains. Some balers feature advanced automation, cutting operational time and minimizing human error. However, lower-capacity models can still be effective for smaller operations, costing less but requiring more manual handling.

Cost is another critical element to consider. Maintenance can consume around 5-10% of total operating costs. Older models might require more frequent repairs, leading to hidden expenses. A detailed evaluation of each baler's specifications, lifecycle costs, and potential downtime is essential. Industry studies indicate that unexpected downtime can cost facilities thousands of dollars in lost productivity. Balers need to be selected wisely to ensure both efficiency and cost-effectiveness in metal recycling operations.

When it comes to ferrous balers, real-world applications highlight their importance. Companies often share experiences on how these machines boost efficiency. For instance, a recycling center reported a 30% increase in throughput after integrating a new baler. Workers found that the machine minimized downtime, allowing them to handle larger volumes of scrap metal. The compacted bales saved space and reduced transportation costs.

User reviews often pinpoint specific advantages. Many operators appreciate the ease of maintenance and user-friendly controls. However, some highlighted challenges with machine calibration. Incorrect settings can lead to inadequate bales, increasing waste. Operators need to regularly assess their processes to ensure optimal performance.

Case studies provide insights into the necessity of proper training. One user observed that staff who received thorough training saw better results. On the other hand, teams that skipped training faced operational setbacks. This shows that while ferrous balers can significantly enhance recycling efforts, factors such as training and calibration play a crucial role in maximizing their potential. The experiences shared by users underline the need for continuous improvement in the recycling process.